Winter operations, whether low-season chartering, lay-up, reduced crew, or extended marina stays, drastically change how onboard water systems are used. Lower occupancy, closed guest areas, and irregular flushing create long water age throughout the yacht’s distribution network. This stagnation does not only increase the risk of Legionella, it also drives proliferation of other key indicator and opportunistic bacteria such as:

- Heterotrophic Plate Count (HPC)

- Total Coliforms

- Escherichia coli (E. coli)

- Enterococci

- Pseudomonas aeruginosa

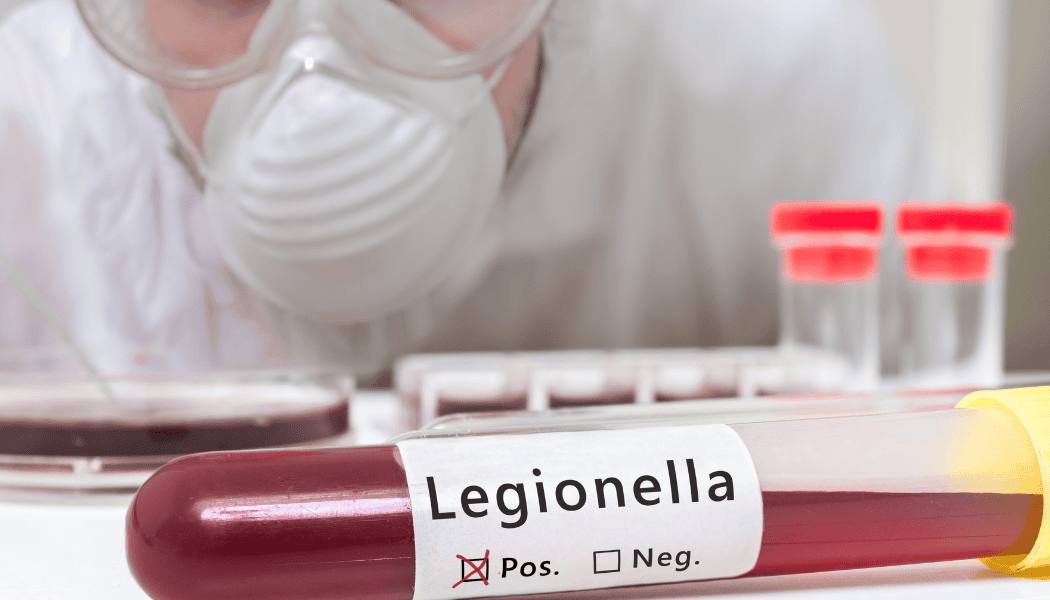

- Legionella pneumophila

These organisms form and persist within biofilms that develop in pipes, flexible hoses, tank deposits, filter housings, and fixtures when disinfectant levels fall and temperatures drift into favourable growth ranges.

The Winter Risk Drivers Onboard

Yacht potable water systems face unique challenges in winter:

- Reduced water movement due to fewer users and closed-off zones during refits

- Disinfectant decay during stagnation

- Temperature drift of cold lines passing through warm spaces

- Biofilm establishment on pipe surfaces and inside hoses

- Infrequent monitoring of sentinel points and tank levels

These conditions provide an ideal environment for bacteria to colonise and multiply.

How Each Bacteria Responds to Winter Conditions

| Organism | Winter Risk Mechanism | Why It Matters on Yachts |

| HPC | Rapid multiplication in stagnant water and biofilm | Indicator of system hygiene and biofilm activity; high counts precede pathogen detection |

| Coliforms / E. coli | Enter via bunkered water or contamination during maintenance | Compliance-critical; presence indicates faecal contamination risk |

| Enterococci | Survive disinfectant depletion and stagnation | Persistence indicates serious hygienic and tank integrity failures |

| P. aeruginosa | Thrives in warm pipes, filters, and hoses; resistant to many biocides | Linked to shower aerosols, jacuzzi systems, and hospital-grade infections |

| Legionella | Multiplies between 20–47 °C; thrives in stagnant pipework | Aerosol transmission via showers, whirlpools, misting systems; regulatory scrutiny |

Cold Water Is Not Safe by Default

Many assume cold water presents low risk. However, when vessels are berthed or in a shipyard period with minimal usage:

- Cold loops in engine rooms or internal spaces heat above 20 °C

- Low disinfectant residuals allow HPC and P. aeruginosa to establish

- Any coliform contamination entering from bunkered water progresses unchecked

This risk increases when flexible hoses such as standard garden type bunker hoses which are not anti microbal or bacterialstatic, leach organic carbon and support microbial growth.

Regulatory and Best Practice Expectations

Maritime health standards, WHO potable water guidance, and ship sanitation inspection regimes require year-round microbiological control. Seasonal lay-ups do not exempt vessels from:

- Routine water testing

- Maintaining safe temperatures and disinfectant levels

- Documenting flushing procedures

- Ensuring potable water tanks, hoses, and filters are clean and maintained

Failure to do so may affect commercial operation, flag compliance, insurance coverage, and port health clearance.

Winter Microbial Control Checklist for Yachts

- Review water system maps and usage patterns

Identify all low-use outlets, technical showers, Jacuzzi feeds, washdown taps, and guest fixtures. - Fight stagnation

Flush ALL outlets at least once per week during lay-up, 2-3 times for high-risk zones. Document flow time until stable temperature and disinfectant achieved. - Maintain disinfectant residuals

Monitor and record disinfectant levels. Any drop may indicate biofilm presence and allow HPC levels to rise unchecked. - Control temperatures

Keep hot water above 55 °C at the tank and ensure distal outlets meet required setpoints. - Manage filters and hoses

Disinfect filter housings, replace cartridges. Avoid long-term storage with water trapped inside. Replace braided stainless hoses, silicone, or rubber tubing showing biofilm or stagnation signs. - Verify and validate your Water Safety Plan

Verification ensures tasks are performed; validation confirms they are effective. Winter is the best time to tighten documentation.

Communicating the Risk to Owners, Captains, and Crew

Winter does not reduce microbiological risk—it shifts it.

Less usage = more stagnation (stagnation occurs after 24-48 hours of no use)

More stagnation = higher HPC, disinfectant loss, and biofilm formation

Biofilm = fertile ground for Legionella, P. aeruginosa, and other water borne pathogens

The message is simple: empty cabins, closed decks, and idle plumbing make winter the highest-risk season for microbial growth.

Modern Approach: Monitoring + Targeted Treatment

Relying solely on periodic sampling is outdated. The most resilient yachts combine:

- Weekly testing for sterilization residual, temperature, pH and conductivity

- Residual disinfectant management (addapting the amount dosed to the current situation)

- Scheduled flushing and verification logs

This creates a stable system that resists microbial colonisation year-round.

Bottom Line for Yacht Crews

Winter is not a microbiological holiday.

To prevent HPC, coliform, E. coli, enterococci, P. aeruginosa, and Legionella contamination:

✔ Keep water moving by weekly flushing of little used outlets.

✔ Maintain disinfectant residuals

✔ Replace vulnerable hoses and maintain monthly filter change

✔ Verify and document compliance

A proactive winter plan protects the crew, guests, and vessel reputation. Ignoring it risks costly remediation, failed inspections, and operational delays when the season begins.

Copyright® Octo Marine SAS – Author Dustin Wilson – November 2025

#BiofilmAware #YachtWaterTreatment #Yachts #WaterTreatment #WaterAnalysis

📍 For more details contact Octo Marine : www.octomarine.com